The inverter control system is based on inverter module, PLC, sensors and other components. The PLC is used to collect the inverter cabinet data and sensor data through communication, while controlling the inverter to change the motor speed and steering, and to achieve PID closed-loop control.

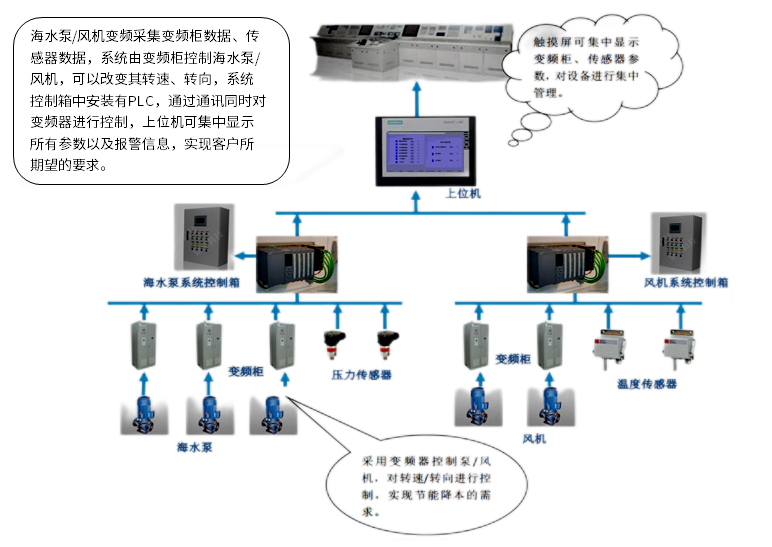

l Seawater pump/fan frequency control system

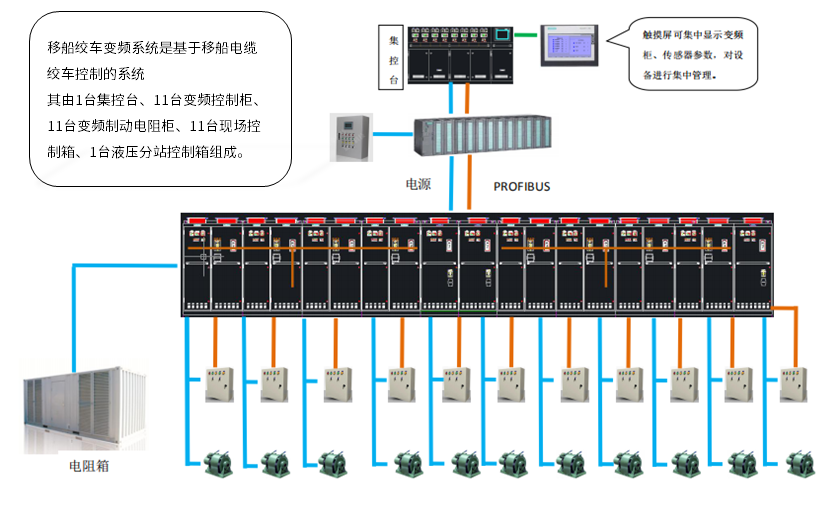

l Ship-shifting winch frequency conversion system

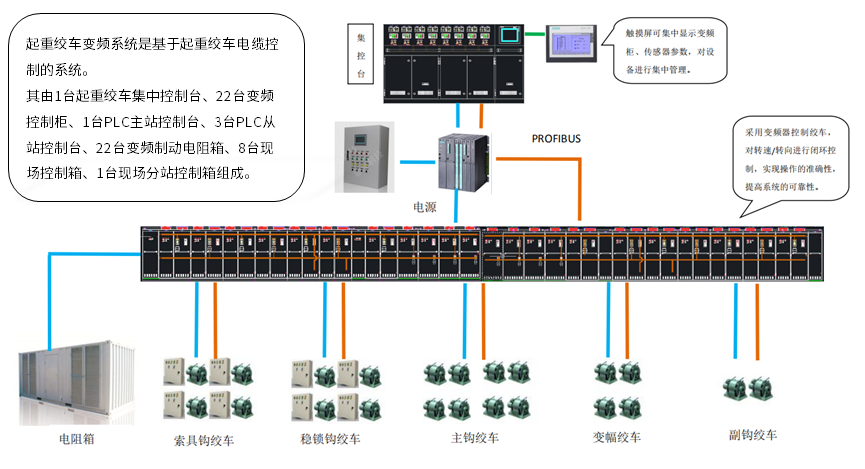

l Crane winch frequency conversion system

The sea water pump/fan inverter collects the inverter cabinet data, sensor data and the system controls the seawater pump/fan by the inverter cabinet, which can change its speed and steering. PLC is installed in the system control box to control the inverter at the same time through communication, and the upper computer can display all parameters as well as alarm information centrally to realize the requirements expected by customers.

The crane winch frequency conversion system is based on the crane winch cable control system.

It consists of 1 centralized console for lifting winch, 22 inverter control cabinets, 1 PLC master console, 3 PLC slave consoles, 22 inverter braking resistor boxes, 8 field control boxes and 1 field substation control box.

The ship-shifting winch frequency conversion system is based on the ship-shifting cable winch control system

It consists of 1 central control console, 11 inverter control cabinets, 11 inverter braking resistor cabinets, 11 field control boxes and 1 hydraulic substation control box.